AI in the Kitchen: Can Technology Prevent the Next Outbreak?

Imagine a kitchen where thermometers never forget, cameras quietly watch handwashing stations, and algorithms flag potential contamination before a single guest takes a bite. This isn’t science fiction — it’s the promise of artificial intelligence in food safety.

As AI systems creep into menu design, inventory tracking, and customer service, the next frontier is compliance. The question is: can technology really prevent the next outbreak, or is it just another shiny tool in a business already stretched thin?

Why It Matters

- Who it affects: Operators of restaurants, hotels, institutional kitchens, and franchises looking to modernize safety systems.

- What it is: AI-driven tools that monitor temperatures, analyze inspection data, detect contamination risks, and even coach staff in real time.

- Where it happens: From line kitchens outfitted with smart sensors to cloud-based compliance platforms tracking multiple locations.

- When it matters most: During peak service, overnight storage, and inspection cycles — when human error is most likely.

- Why it’s critical: Studies show that human error is the leading cause of food safety lapses. AI doesn’t get tired, distracted, or skip steps during a rush.

Case in Point

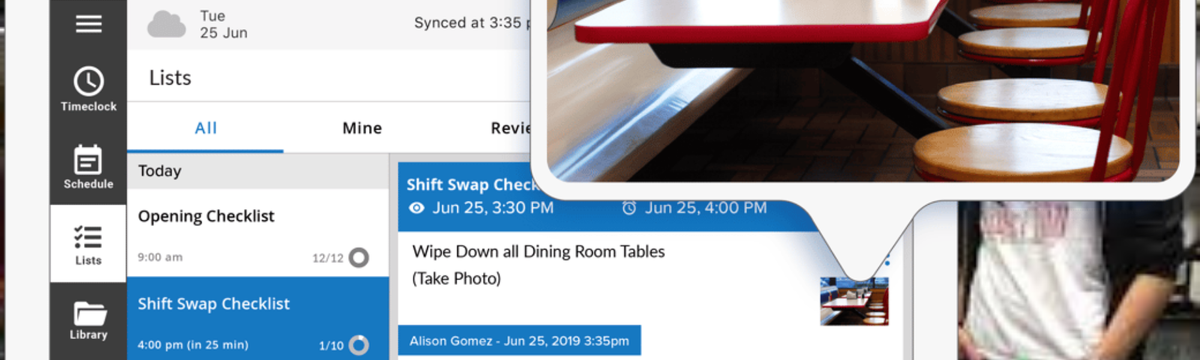

In 2023, a pilot program in Washington, D.C., partnered a national fast-casual chain with an AI-driven monitoring system. Sensors tracked refrigeration units, while cameras monitored glove changes and handwashing compliance. Within six months, the chain reported a 30% drop in critical violations compared to previous inspection cycles.

The technology didn’t replace managers — it supported them. Alerts flagged issues before they escalated, giving staff a chance to correct mistakes in real time.

Opportunities & Limits

AI has clear advantages:

- Consistency: Unlike humans, systems don’t fatigue or cut corners.

- Data: AI can analyze thousands of inspection reports to identify patterns and risks.

- Training: Video and sensor feedback can be used in staff coaching.

But it’s not a silver bullet.

- Costs: Sensors, software, and integrations aren’t cheap — especially for independents.

- Privacy: Cameras in kitchens raise questions about staff monitoring.

- Dependence: AI systems still require human oversight and judgment.

How Operators Can Prepare

- Start small: temperature sensors or smart thermometers are a low-cost entry point.

- Evaluate vendors: ensure data is secure and systems comply with local labor laws.

- Train staff to view AI as a partner, not a punishment tool.

- Use AI data to reinforce — not replace — daily food safety culture.

Checkout our resource center for valuable downloads

Final Thought

AI in the kitchen isn’t about replacing people — it’s about preventing the mistakes people inevitably make. The future of food safety will blend human judgment with machine precision. Operators who embrace that balance may not just survive the next inspection — they may prevent the next outbreak altogether.

Advance your kitchen with Certivance. Our qualified team has partnered with the industry leading technologies to bring your facility to today and beyond.