How to Ace a Surprise Inspection This Fall

It’s a crisp October afternoon. Pumpkins line your host stand, the fryer is working overtime on game-day wings, and the dining room is packed with flannel-clad families. The last thing you expect is the health inspector stepping through the door, clipboard in hand.

Surprise inspections don’t come with warning calls or calendar invites. They arrive in the middle of your busiest shifts, at the tail end of deliveries, or just when your dishwasher breaks down. For operators, the difference between panic and confidence comes down to preparation.

Why Surprise Inspections Matter

Surprise visits are designed to capture the real state of your operation — not the polished version you’d show off if given notice. Inspectors want to see how you run on a normal day, in normal conditions. That’s why fall inspections can sting: cooler weather and heavier menus bring new risks, from soups and stews cooling too slowly to cross-contamination with seasonal produce.

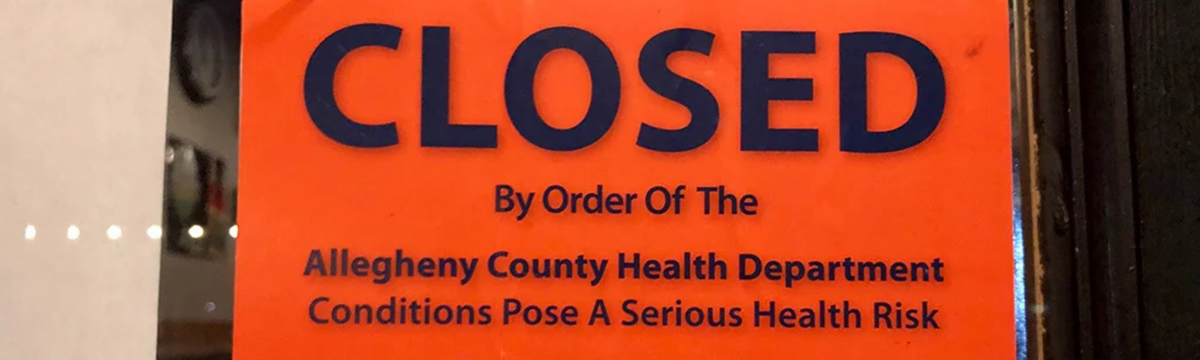

And here’s the truth: a single bad surprise inspection can ripple out for months. Reports are public. Guests read them. Local news sometimes amplifies them. And competitors won’t hesitate to point them out.

Case in Point

In 2023, state inspectors in Maryland cited a popular Baltimore restaurant during a surprise visit for multiple violations, including improper cooling of chili and soup left on counters for hours. Guests weren’t sickened, but the violations were enough to force a temporary closure and splash the restaurant’s name across local headlines.

The lesson wasn’t just about soup. It was about systems. The restaurant had checklists, but staff weren’t following them consistently — and the inspector saw the cracks.

How to Stay Ready Without Losing Your Mind

The best operators don’t “cram” for inspections. They build habits so solid that a surprise visit looks like just another shift.

Take temps daily — not because the inspector might come, but because food safety depends on it. Keep sanitizer buckets fresh and labeled. Make sure staff know where their food handler cards are. And perhaps most important, coach your team not to panic. Inspectors are professionals; they’re not out to “get you.” They’re there to confirm what you should already be doing: keeping guests safe.

Fall brings unique wrinkles, too:

- Cooler weather means soups, sauces, and gravies need rapid cooling systems to avoid the danger zone.

- Holiday prep can clutter storage areas — inspectors notice when food is blocked by decorations, catering trays, or unopened deliveries.

- Seasonal staff rotations can expose training gaps.

When those risks are addressed before the inspector ever arrives, surprise visits lose their sting.

Use our Inspection Checklist and checkout our resource center for valuable downloads

Final Thought

A surprise inspection isn’t really a surprise if you’ve built the right culture. By treating every shift like inspection day, you turn what could be a moment of fear into a moment of confidence. Guests may never see the inspector’s report, but they’ll feel the difference in the safety and trust your operation delivers.